Predictive Maintenance in Industry 4.0

Predictive maintenance is one of the main benefits deriving from Industry 4.0. This is an intelligent type of maintenance, capable of estimating the residual life time of machinery and components to improve the reliability of the entire system. This happens thanks to the continuous data analysis created by the machinery which is connected to a network.

There are two main advantages that can be ensured by the correct implementation of a predictive maintenance strategy: predicting when failures may occur and being able to schedule timely interventions, thus reducing costly downtime and plant shutdowns as well as spare parts costs.

In the long term, companies can count on an extension of the useful life cycle of their machines, also reducing the costs associated with spare parts in the warehouse. Therefore, companies that are able to consistently apply this type of strategy can count on evident savings, in terms of maintenance costs and a significant productivity gain.

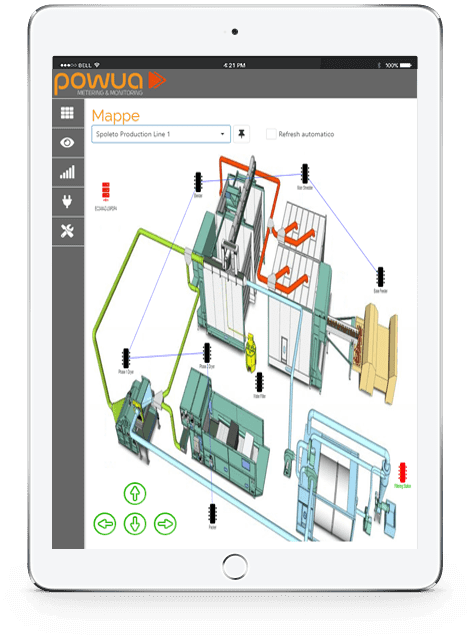

From an infrastructural point of view, setting up correct Predictive Maintenance is anything but simple and obvious, considering the heterogeneity of machinery and solutions present in real industrial contexts. Powua – the Avantune platform of IoT Orchestration, allows one to acquire data in real time from heterogeneous devices, interfacing PLC (Programmable Logic Controller), sensors and intelligent machinery, and can be connected to external data sources such as SCADA, ERP, MES and CMMS.

Features

✓ Il monitoraggio delle risorse

✓ La misurazione delle performance

✓ Analisi dei dati ottenuti

✓ Condivisione delle informazioni con gli operatori

Powua permette la gestione ed il controllo di dispositivi e macchinari in modalità self-service. Grazie ai moduli di metering e monitoring, e all'abilitazione di sensori IoT è possibile ricevere in unica dashboard tutte le misurazioni, impostare soglie di allarme e ricevere i segnali di incidenti. Grazie ai data insights generati dall’intelligenza artificiale e dagli algoritmi di apprendimento automatico, è possibile infine intervenire rapidamente senza dover sospendere i servizi.

✓ Resource monitoring

✓ Performance measurement

✓ Analysis of the data obtained

✓ Sharing of information with operators

Powua allows the management and control of devices and machinery in self-service mode.

Thanks to the metering and monitoring modules, and the enabling of IoT sensors, it is possible to receive all measurements in a single dashboard, set alarm thresholds and receive incident signals.

Thanks to the data insights generated by artificial intelligence and machine learning algorithms, it is finally possible to intervene quickly without having to suspend services.

Alert

With the metering / monitoring module it is possible to process and correlate the information detected, to set critical thresholds that activate alerts and interventions, for each machine or component.

Sensors

Smart sensors allow one to carry out diagnostics, to detect significant parameters from the system and represent a powerful tool serving as a failure prevention.

Benefits

CONTROL

MEASURE

FORECAST